Installing and Seaming the

Drywall

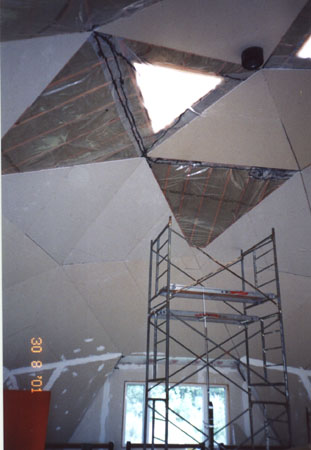

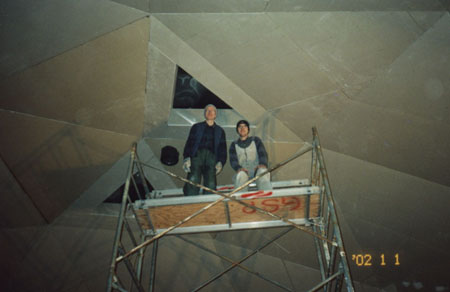

Half-inch gypsum dry-wallboard was screwed

to the interior of the dome shell, and the seams were taped and

seamed. While none of these steps were difficult, it was somewhat

time consuming, as much of the work was done off scaffold. Only

minimal amounts of waste were generated, as triangle cutting

generally made good use of the full 4 x 12 foot gyproc panels.

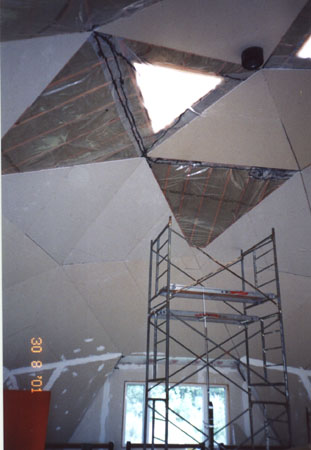

The seaming between the vapour barrier

sheets is visible in these pictures. We did try to be very careful to

seal all the seams to prevent moisture ingress into the ceiling, as

trapped moisture would have no path to escape.

The seaming between the vapour barrier

sheets is visible in these pictures. We did try to be very careful to

seal all the seams to prevent moisture ingress into the ceiling, as

trapped moisture would have no path to escape.

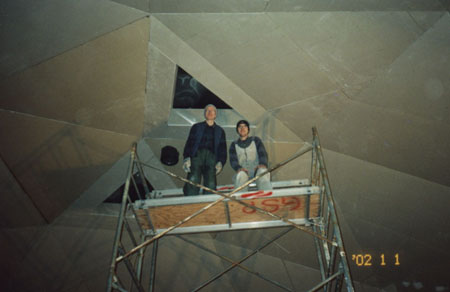

Finally, on January 1st, 2002, the last

section of the drywall installation was completed. Now on to

seaming!

Finally, on January 1st, 2002, the last

section of the drywall installation was completed. Now on to

seaming!

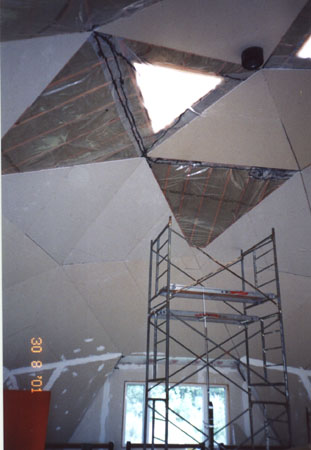

Seaming was carried out from the top ring

down, generating interesting patterns, resembling giant spider

webs.

Seaming was carried out from the top ring

down, generating interesting patterns, resembling giant spider

webs.

By mid June, 2002 the first of three coats

of drywall "mud" was added to the last of the seams at the bottom of

the dome. Sanding and a second coat of seam compound was applied from

the top down. The seam was sanded a third time and finish seaming was

carried out a ring at a time, followed by final sanding and painting

(primer coat and then finish ceiling coat) as each ring of drywall

was completed from the top down.

By mid June, 2002 the first of three coats

of drywall "mud" was added to the last of the seams at the bottom of

the dome. Sanding and a second coat of seam compound was applied from

the top down. The seam was sanded a third time and finish seaming was

carried out a ring at a time, followed by final sanding and painting

(primer coat and then finish ceiling coat) as each ring of drywall

was completed from the top down.

Return to the first

construction page

Return to the first

construction page

Go to the next construction page-The

Waste Water System

Return to TRI-LEA-EM