The TRI-LEA-EM Electrical

System

The TRI-LEA-EM dome site is some 1500 feet (500 metres)

away from the road and electrical power distribution. In part for

this reason (access would have required a long and expensive pole

line) and in keeping with the desire for TRI-LEA-EM to act as an

environmental demonstration site, an off-grid electrical system was

installed. The system design criteria was as follows:

- building electrical usage estimated for 2 days in a weekend at

8400 watt hours

- 100 watt air to air heat exchanger motor for 16 hours = 1600

watt hours

- 10 x 15 watt compact fluorescent lamps for 8 hours = 1200 watt

hours

- water pump - 1/2 hp ~ 375 watts for 2.7 hours = 1000 watt hours

- projection equipment - 1000 watts x 3 hours = 3000 watt hours

- computer - 150 watts x 3 hours = 450 watt hours

- microwave - 800 watts x 1 hour = 800 watt hours

- audio equipment - 50 watts x 8 hours = 400 watt hours

Battery Rating Chosen - 700 Amp Hours at 24 volts = 16,800

watt hours, so that only half of the battery would be discharged in a

2 day usage period. 8 Trojan L16 cells were installed.

550 watts of Solar Panels (10 x Siemens SM-55) were

installed, originally chosen due to their compact physical size, with

the intent for direct roof top mounting. This was subsequently

revised to use pole mounting at the south facing dome side, to avoid

damaging the roof shingles. The intent was that the solar panels

could recharge the battery over a week assuming 2.2 hours of direct

sunshine per day x 7 days x 550 watts = 8400 watt hours. A Trace C-40

charge controller controls charging. The solar panels and related

equipment were supplied by

Backwoods Solar Electric

Systems, of Sandpoint, Idaho, and the inverter and batteries by

The Battery Post, Burlington, Ontario.

Home Power Magazine was a

great help in thinking out the system design, and John Wiles and Joe

Schwartz, both of whom write for Home Power Magazine were very

helpful in responding to questions about details before installation.

We thank them for their aid. It was a fun learning experience, and

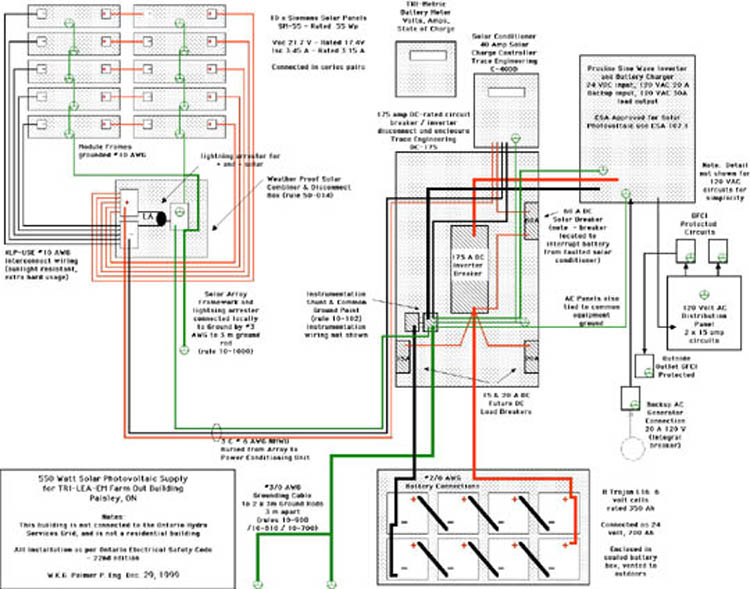

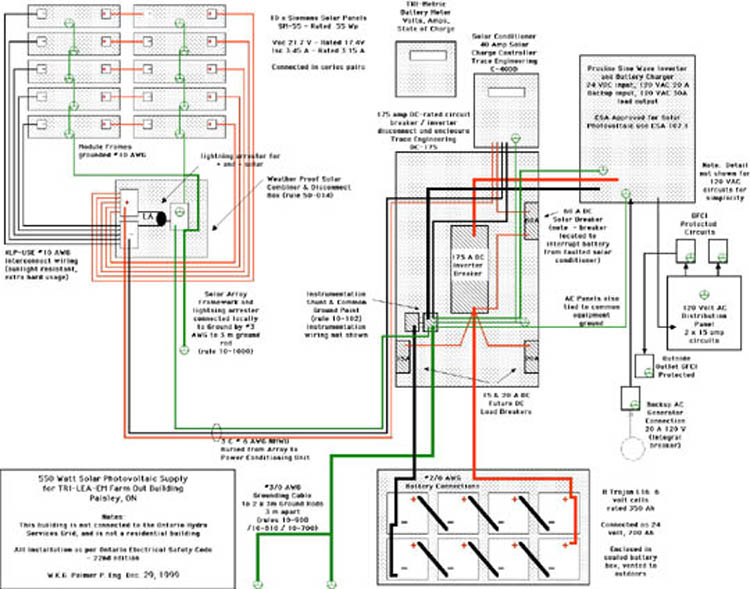

has worked well. A schematic diagram of the system is shown below and

photos of the installed equipment. The TRI-LEA-EM site also has a

reliable wind resource, and some day a wind turbine may join the

solar panels, in particular for winter time support, but this has not

been required. The nice thing about solar panels is that their low

maintenance needs - occasionally sweep off snow during the winter

(although most just falls off) and water the batteries periodically

(which would also be needed with a wind based system). A gasoline

powered generator can be connected to charge the batteries in the

event of high demand and low sun, but so far it has only run about 2

hours in 4 years!

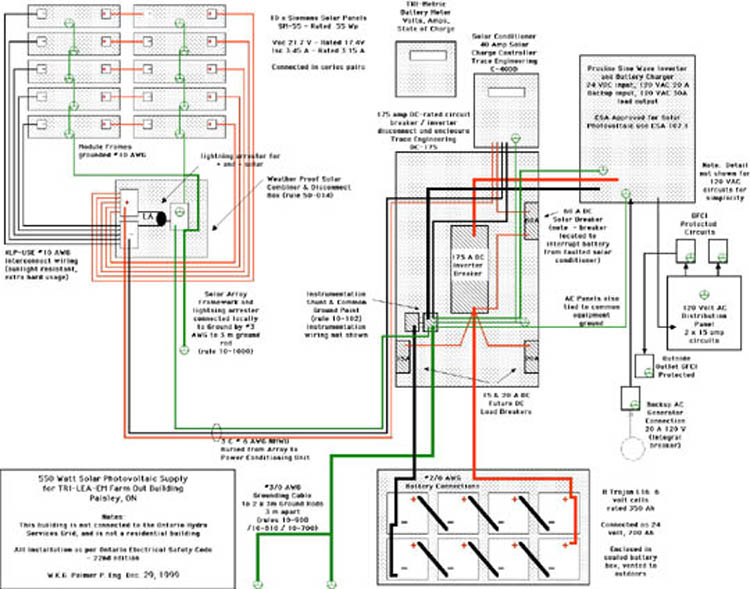

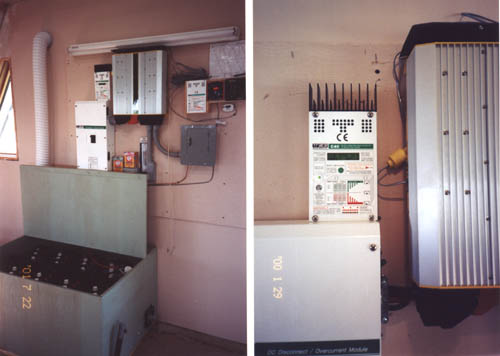

The ventilated battery box sits below the charge

controller, the DC disconnect, and the inverter. Metering in the C-40

provides information on solar input, and accumulated solar in, and a

Trimetric Battery Monitor shows battery state of charge, and load

conditions. The Prosine 2500 Watt inverter was chosen as it supplies

a clean sine wave signal for computer, audio equipment, and

projection equipment as well as a built in charger that can be

supplied by the generator.

The ventilated battery box sits below the charge

controller, the DC disconnect, and the inverter. Metering in the C-40

provides information on solar input, and accumulated solar in, and a

Trimetric Battery Monitor shows battery state of charge, and load

conditions. The Prosine 2500 Watt inverter was chosen as it supplies

a clean sine wave signal for computer, audio equipment, and

projection equipment as well as a built in charger that can be

supplied by the generator.

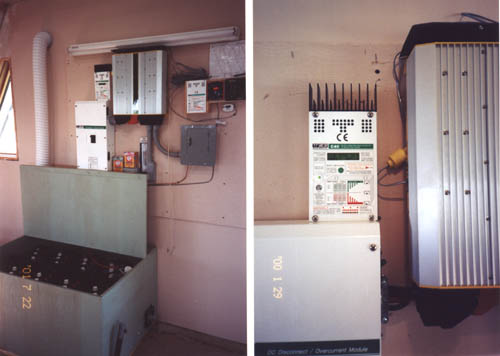

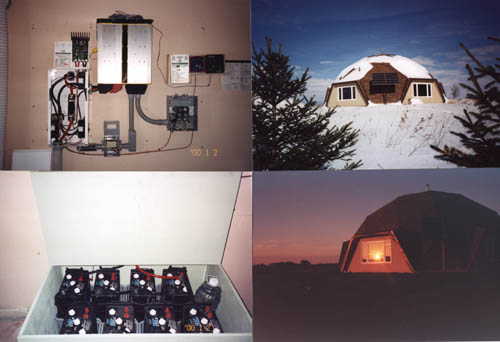

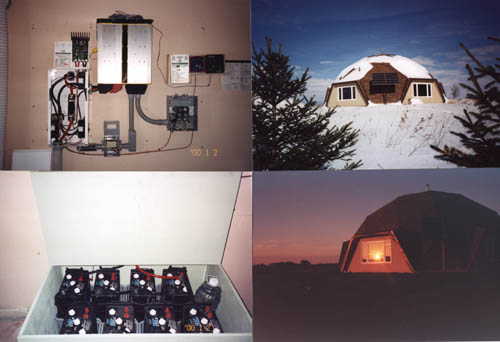

This composite shows the system being installed (covers

are not normally off!), the battery box, the solar panel mount (on a

schedule 40-4 inch pipe embedded in a concrete footing), and the

source of the energy (reflected in the building windows late one fall

evening).

Return to the first

construction page

This composite shows the system being installed (covers

are not normally off!), the battery box, the solar panel mount (on a

schedule 40-4 inch pipe embedded in a concrete footing), and the

source of the energy (reflected in the building windows late one fall

evening).

Return to the first

construction page

Go to next construction page -

Completing the Interior

Return to TRI-LEA-EM